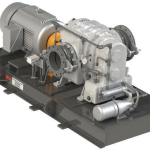

Yuniqtech LLC Pumps recognizable frame design incorporating mounting surfaces rather than mounting feet, lets you know it’s a quality Cornell Pump frame supporting a robust Yuniqtech LLC pump. The feet can be useful and space-saving in food plant mountings.

| Model | Discharge | Suction | Solids Handling | Data Sheet |

| 3NLP | 3" | 3" | 2" x 3" | Data Sheet |

| 4NMP | 4" | 4" | 2.94” x 4.0” | Data Sheet |

| 4NMPP | 4" | 4" | 2.94” x 4.0” | Data Sheet |

| 6NHP | 6" | 6" | 4”x6” | Data Sheet |

| 6NHPP | 6" | 6" | 4” x 6” | Data Sheet |

| 8NHPP | 8" | 8" | 5” x 9” | Data Sheet |

| 10NHPP | 10" | 10" | 7.5” x 12” | Data Sheet |

| 12NHPP | 12" | 12" | 8.75” x 14” | Data Sheet |

P Series

The P-series pumps feature a discharge size ranging from 3″ to 6″, with flows up to 1,700 GPM and heads up to 100 feet. Capable of handling large size solids.

PP Series

The P-series pumps feature a discharge size ranging from 4″ to 12″, with flows up to 8,300 GPM and heads up to 165 feet. Capable of handling large size solids.

GXT-HTF Pumps have been designed into just about any food application imaginable, including

- Potatoes

- French Fries

- Potato Chips

- Live Fish

- Cranberries

- Carrots

- Apples

- Cherries

- Peas

- Broccoli

- Crayfish

- Shrimp

- Lettuce

- Green beans

- Nuts

- Peppers

- Olives

- Cucumbers

- Raisins

- Beans

- Corn

- Peaches

- Beets

- Oranges

Features & Benefits

- Ductile iron construction

- Oversized, offset volute

- Robust Mount Frame with mounting surfaces

- No volute cutwater

- Single vane impeller

- Smooth contours

- Reduced product damage

- Low cost of repair

- Threaded impeller

- Food grade packing

- No product contamination

- Heavy “stressproof” steel shaft

- Cycloseal® sealing system Available

- Back-to-back double lip seals

- Extended mechanical seal life

- Oversized bearings with extended life

- Replaceable shaft sleeve

- Dynamically-balanced impeller

- Stainless Steel option

- Two-year warranty